1. Overview

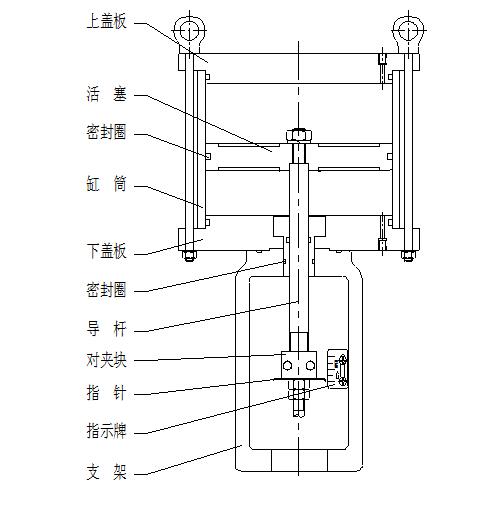

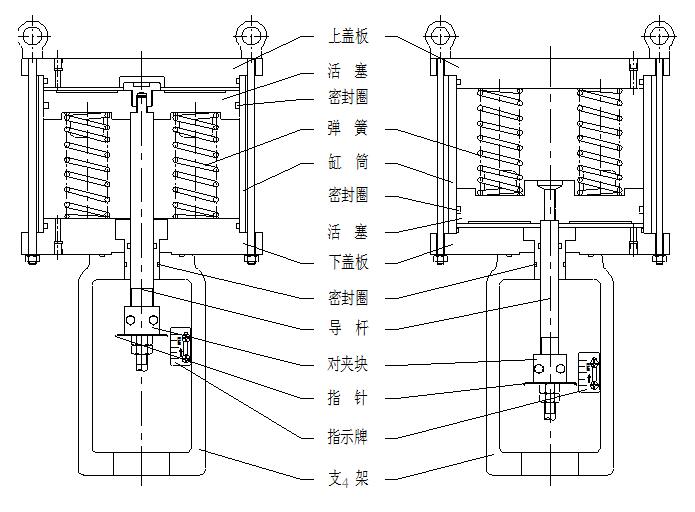

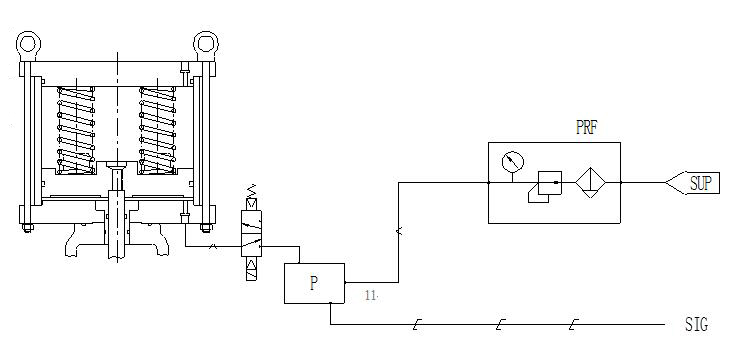

| This series is a pneumatic piston actuator with large output force and high performance. It is used in combination with straight-stroke control valves, including globe valves, cage valves, gate valves, etc. The design of this series of actuators can make the control valve reliable on-off or regulating control. This series of actuators are divided into two types, single-acting and double-acting. Single-acting actuators are divided into two types, direct-acting (GD-Z) and counter-acting (GD-F). They are spring-loaded cylinder-type actuators; and double-acting (GD-F) -D) The actuator is a cylinder type actuator that is controlled by air pressure without spring loading, and its mechanism positions the valve core according to the constantly changing pneumatic loading pressure on the cylinder. See the figure on the right for an example of a pneumatic piston actuator. |  |

| Installation example |

2. Standard Specification

Series | GD | |

Specification | 20、30、31、40、41、42、43、50 | |

Output Method | Straight stroke | |

Action | Double acting: GD-D Single action: GD-Z (positive action), GD-F (reverse action) | |

Maximum output thrust | See table 1 | |

Stroke | See table 1 | |

Air pressure | 600Kpa | |

Piping interface | Please refer to pages 8-12 | |

Ambient temperature | Standard type: -40℃~82℃ Special type (optional): -18℃~149℃, -54℃~149℃ | |

Spring range | Positive effect:20~100Kpa、80~200Kpa | |

Material of main parts | Standard | Upper and lower cover plates: Steel Sealing ring: Viton O-ring: Nitrile rubber, Stroke indicator: stainless steel Pointer: stainless steel Actuator spring: spring steel, Actuator guide rod: steel Wafer block: galvanized steel surface Bracket: cast iron, Piston: Steel Pillar: Steel Cylinder: Steel, Hand wheel: ductile iron |

Special type | Sealing ring, O-ring: Viton (-18℃~149℃), silicone synthetic rubber (-54℃~149℃), Upper and lower cover: stainless steel Actuator guide rod: stainless steel Column: stainless steel, Piston: Stainless Steel Cylinder: Stainless Steel | |

Painting color | Orange | |

Attachment | Positioners, air filter pressure reducers, limit switches, solenoid valves, retaining valves, amplifiers, etc. | |

Optional equipment | Manual operating mechanism, special air piping and special air joints, high temperature environment, low temperature environment, salt corrosion type, designated coating color, etc. | |

Figure 1 Structure

Figure 1-1 Double acting

Figure 1-2 Single acting

GD-Z type (positive acting-air shut type) GD-F type (reaction-air open)

Table 1 Output thrust, stroke and weight

Executive agency | Rated stroke (mm) | Effective area of cylinder(cm2) | Turn off the thrust(kgf) | Spring pressure(Kpa) | Operating pressure(Kpa) | Approximate weight(kg) | ||||

Types | Series | Specification | Without handwheel | Top loading handwheel | Side-mounted handwheel | |||||

GD-Z | 22 | 20 | 38 | 380 | 1520 | 20~100 | 600 | 32 | 45 | 65 |

33 | 30 | 51 | 706 | 2824 | 56 | 64 | 72 | |||

31 | 76 | 61 | 69 | 77 | ||||||

44 | 40 | 76 | 1385 | 5540 | 92 | 105 | 123 | |||

41 | 102 | 98 | 111 | 129 | ||||||

42 | 127 | 103 | 116 | 134 | ||||||

43 | 200 | 112 | 125 | 143 | ||||||

55 | 50 | 200 | 2289 | 9156 | 123 | 142 | 156 | |||

GD-Z-T | 22 | 20 | 38 | 380 | 1216 | 80~200 | 600 | 33 | 46 | 66 |

33 | 30 | 51 | 706 | 2259 | 57 | 65 | 73 | |||

31 | 76 | 62 | 69 | 78 | ||||||

44 | 40 | 76 | 1385 | 4432 | 93 | 106 | 124 | |||

41 | 102 | 99 | 112 | 130 | ||||||

42 | 127 | 105 | 118 | 136 | ||||||

43 | 200 | 114 | 127 | 145 | ||||||

55 | 50 | 200 | 2289 | 7325 | 125 | 144 | 158 | |||

GD-F | 22 | 20 | 38 | 380 | 760 | 200~300 | 600 | 33 | 46 | 67 |

33 | 30 | 51 | 706 | 1412 | 58 | 65 | 73 | |||

31 | 76 | 64 | 71 | 79 | ||||||

44 | 40 | 76 | 1385 | 1939 | 140~260 | 93 | 107 | 125 | ||

41 | 102 | 99 | 113 | 131 | ||||||

42 | 127 | 106 | 120 | 138 | ||||||

43 | 200 | 117 | 131 | 149 | ||||||

55 | 50 | 200 | 2289 | 3204 | 125 | 144 | 159 | |||

GD-D | 22 | 20 | 38 | 380 | 1900 | Without spring | 600 | 30 | 43 | 63 |

33 | 30 | 51 | 706 | 3530 | 54 | 65 | 70 | |||

31 | 76 | 57 | 68 | 73 | ||||||

44 | 40 | 76 | 1385 | 6925 | 90 | 103 | 121 | |||

41 | 102 | 94 | 107 | 125 | ||||||

42 | 127 | 97 | 110 | 128 | ||||||

43 | 200 | 104 | 117 | 135 | ||||||

55 | 50 | 200 | 2289 | 11445 | 115 | 137 | 148 | |||

Three, other configurations can be provided

Top/side mounting handwheel

To meet manual operation in emergency situations, the GD type actuator can be equipped with a top-mounted or side-mounted handwheel assembly.

The fixed handwheel on the GD type actuator can be used to set the travel limit in the upward direction. The handwheel of GD-Z type actuator rotates clockwise to make the actuator push rod move downward to compress the spring; when the handwheel rotates counterclockwise, the action of the spring pushes the push rod back. For the GD-F type actuator, counterclockwise rotation will move the push rod upward; when it is rotated clockwise, the spring will push the push rod downward.

The side-mounted handwheel on the GD type actuator locates the handwheel on one side of the bracket. Through the worm gear drive, the handwheel drive can also be used as a stroke limiter.

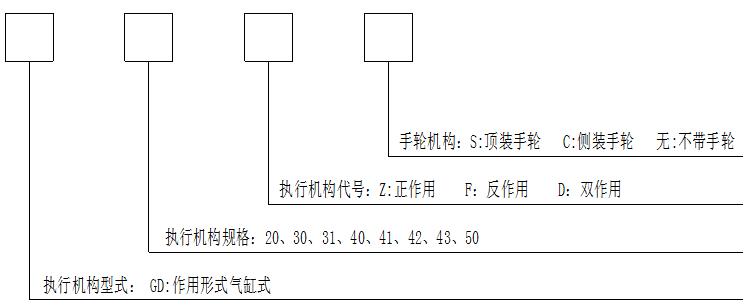

Four, model preparation instructions

Example: Model: GD44-Z-S

Means: Positive-acting actuator, 44 cylinder, with top-mounted handwheel

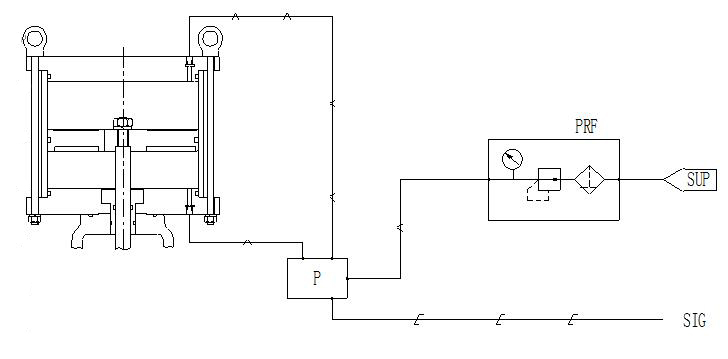

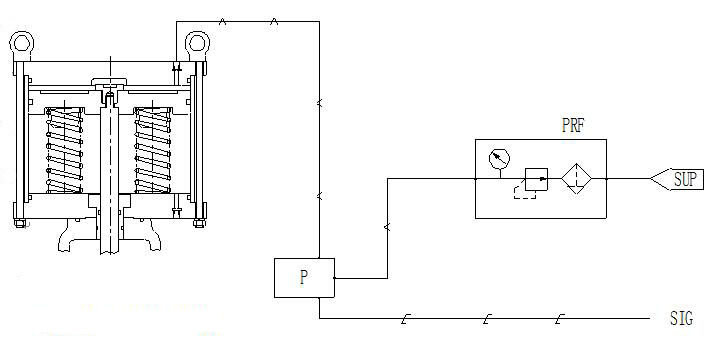

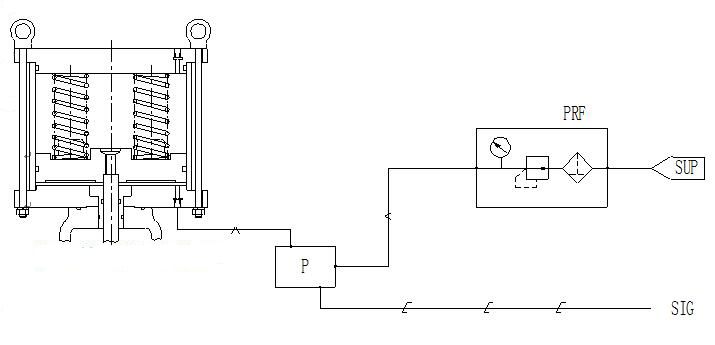

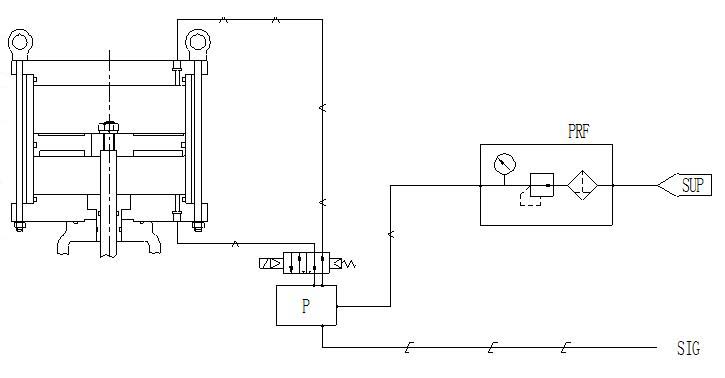

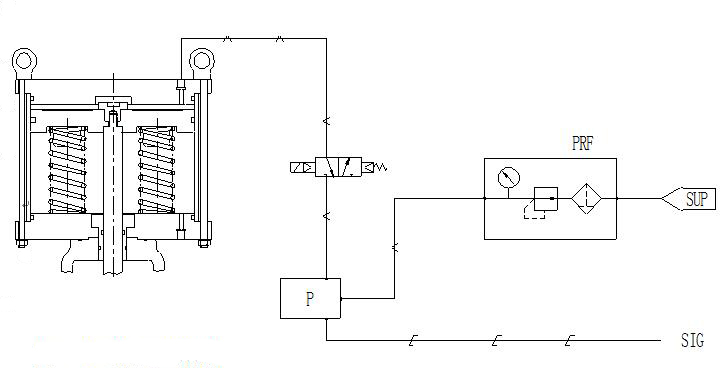

Figure 2 Standard piping circuit

Figure 2-1 Positioner automatic control

Figure 2-1A Double acting

Figure 2-1B Single-acting-positive acting

Figure 2-1C Single-acting-Counter-acting

Figure 2-2 Automatic control of positioner and solenoid valve

Figure 2-2A Double acting

Figure 2-2B Single acting (positive acting)

Figure 2-2C Single action (reverse action)

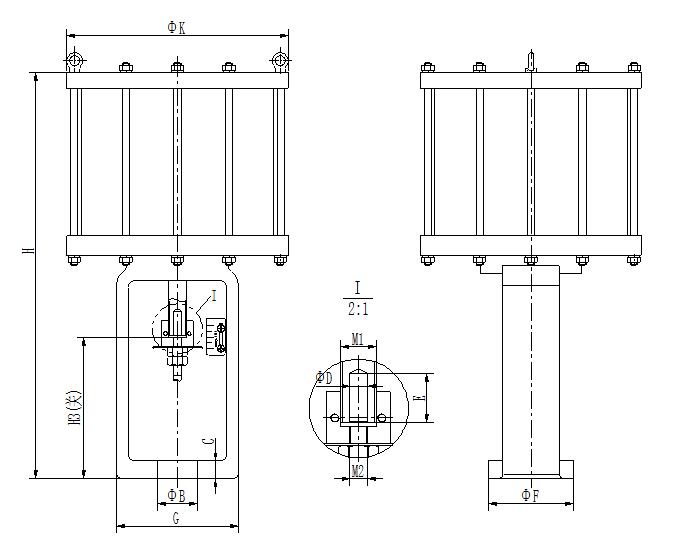

GD type no handwheel mechanism

Size Unit:mm

Series | Specification | Rated stroke | φB | C | φD | E | φF | G | H | H3 (Off) | φK | Air supply piping interface |

22 | 20 | 38 | 71 | 24 | 13.5 | 15 | 138 | 170 | 429 | 123 | 285 | 1/4"NPT |

33 | 30 | 51 | 90 | 35 | 20 | 15 | 160 | 204 | 528 | 172 | 385 | 1/2"NPT |

31 | 76 | 90 | 35 | 20 | 15 | 160 | 204 | 755 | 172 | 385 | 1/2"NPT | |

44 | 40 | 76 | 90 | 35 | 20 | 15 | 200 | 246 | 845 | 186 | 520 | 3/4"NPT |

41 | 102 | 90 | 35 | 20 | 15 | 200 | 246 | 930 | 186 | 520 | 3/4"NPT | |

42 | 127 | 90 | 35 | 20 | 15 | 200 | 246 | 980 | 186 | 520 | 3/4"NPT | |

43 | 200 | 90 | 35 | 20 | 15 | 200 | 246 | 1157 | 186 | 520 | 3/4"NPT | |

55 | 50 | 200 | 90 | 35 | 20 | 15 | 200 | 260 | 1981 | 186 | 660 | 3/4"NPT |

Note: 1. M1 thread size: GD22 series are 3/4"-16UNF; GD33, GD44, GD55 series are 1-1/8"-12UNF;

2. M2 thread size: GD22 series are 1/2"-20UNF; GD33, GD44, GD55 series are 3/4"-16UNF.

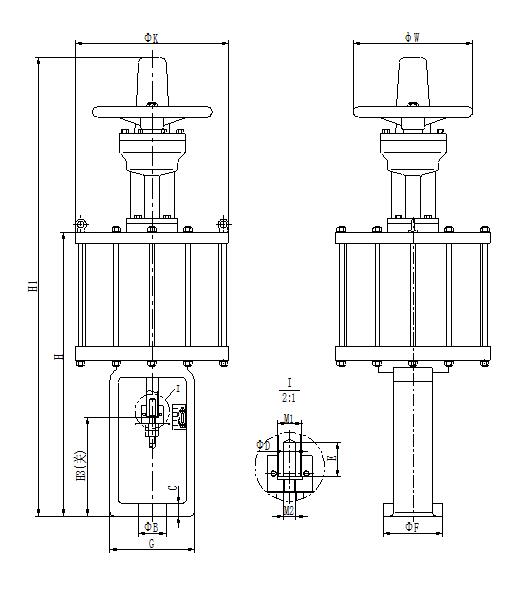

GD top mounted handwheel mechanism

Size Unit:mm

Series | Specification | Rated stroke | φB | C | φD | E | φF | G | H | H1 | H3 | φK | φW | Air supply piping interface |

22 | 20 | 38 | 71 | 24 | 13.5 | 15 | 138 | 170 | 429 | 680 | 123 | 285 | 250 | 1/4"NPT |

33 | 30 | 51 | 90 | 35 | 20 | 15 | 160 | 204 | 528 | 780 | 172 | 385 | 280 | 1/2"NPT |

31 | 76 | 90 | 35 | 20 | 15 | 160 | 204 | 755 | 1150 | 172 | 385 | 280 | 1/2"NPT | |

44 | 40 | 76 | 90 | 35 | 20 | 15 | 200 | 246 | 845 | 1240 | 186 | 520 | 400 | 3/4"NPT |

41 | 102 | 90 | 35 | 20 | 15 | 200 | 246 | 930 | 1360 | 186 | 520 | 400 | 3/4"NPT | |

42 | 127 | 90 | 35 | 20 | 15 | 200 | 246 | 980 | 1360 | 186 | 520 | 400 | 3/4"NPT | |

43 | 200 | 90 | 35 | 20 | 15 | 200 | 246 | 1157 | 1650 | 186 | 520 | 400 | 3/4"NPT | |

55 | 50 | 200 | 90 | 35 | 20 | 15 | 200 | 260 | 1981 | 2550 | 186 | 660 | 400 | 3/4"NPT |

Note:

1. M1 thread size: gd22 series is 3 / 4 "- 16unf; Gd33, gd44 and GD55 series are 1-1 / 8 "- 12unf;

2. M2 thread size: 1 / 2 "- 20unf for gd22 series; Gd33, gd44 and GD55 series are 3 / 4 "- 16unf.

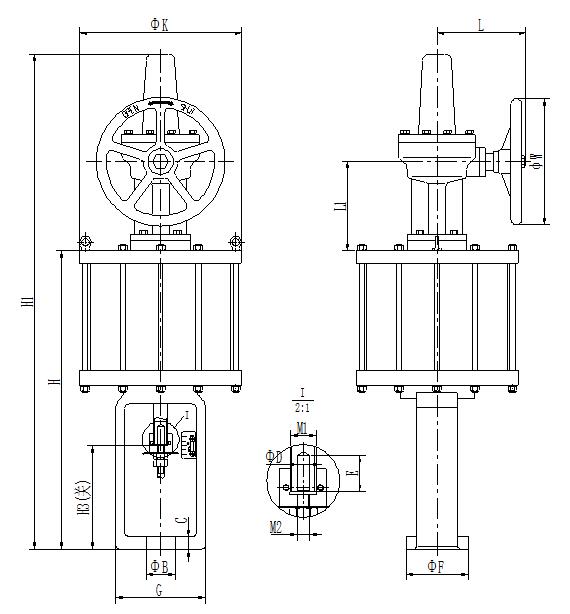

GD type side mounted handwheel mechanism

Size Unit:mm

Series | Specification | Rated stroke | φB | C | φd | E | φF | G | H | H1 | H3 | φK | L | L1 | φW |

22 | 20 | 38 | 71 | 24 | 13.5 | 15 | 138 | 170 | 429 | 680 | 123 | 285 | 220 | 280 | 250 |

33 | 30 | 51 | 90 | 35 | 20 | 15 | 160 | 204 | 528 | 780 | 172 | 385 | 280 | 300 | 280 |

31 | 76 | 90 | 35 | 20 | 15 | 160 | 204 | 755 | 1150 | 172 | 385 | 280 | 300 | 280 | |

44 | 40 | 76 | 90 | 35 | 20 | 15 | 200 | 246 | 845 | 1240 | 186 | 520 | 350 | 350 | 400 |

41 | 102 | 90 | 35 | 20 | 15 | 200 | 246 | 930 | 1360 | 186 | 520 | 350 | 350 | 400 | |

42 | 127 | 90 | 35 | 20 | 15 | 200 | 246 | 980 | 1360 | 186 | 520 | 350 | 350 | 400 | |

43 | 200 | 90 | 35 | 20 | 15 | 200 | 246 | 1157 | 1650 | 186 | 520 | 350 | 350 | 400 | |

55 | 50 | 200 | 90 | 35 | 20 | 15 | 200 | 260 | 1981 | 2550 | 186 | 660 | 380 | 350 | 400 |

Note:

1. M1 thread size: gd22 series is 3 / 4 "- 16unf; Gd33, gd44 and GD55 series are 1-1 / 8 "- 12unf;

2. M2 thread size: 1 / 2 "- 20unf for gd22 series; Gd33, gd44 and GD55 series are 3 / 4 "- 16unf;

3. Size of air supply piping interface: 1 / 4NPT for gd22 series, 1 / 2NPT for gd33 series, and 3 / 4NPT for gd44 and GD55 series.